Shortcomings Of The ZimVie’s Tapered Screw-Vent with Trabecular Metal®

- Controversial issues that affect the dental implant dentistry

Analysis Of The Shortcomings Of The ZimVie’s Tapered Screw-Vent with Trabecular Metal®

- Gerald Niznick

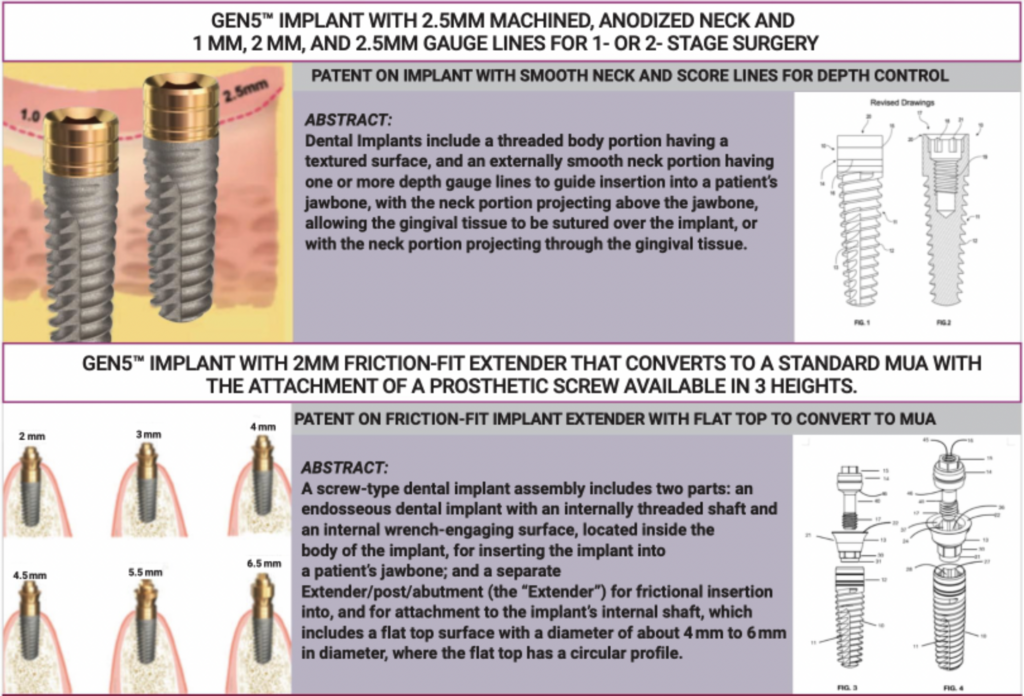

I sold Core-Vent/Paragon to Zimmer Dental (today ZimVie) in 2000 along with the patent on the conical connection and the patent on the friction-fit abutment. For the last 21 years the TSV with its friction-fit abutment has been ZimVie’s flagship product with remarkable success. I formed Implant Direct in 2004 and in 2007, when the patent on the conical connection expired, I launched the next generation of TSV which I called the Legacy implant. Both the TSV and Legacy had the standard Branemark “V” shaped threads but to the Legacy, I added the patented quadruple lead micro-threads above the double lead body threads. In 2008 I designed Legacy2 with progressively deeper flat-based threads. My new implant company, Paragon, is developing the GEN5™ implant with the same body and surface as the Legacy2 but with a 2.5mm machined, anodized neck to accommodate for uneven ridges and subsequent bone remodeling.

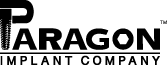

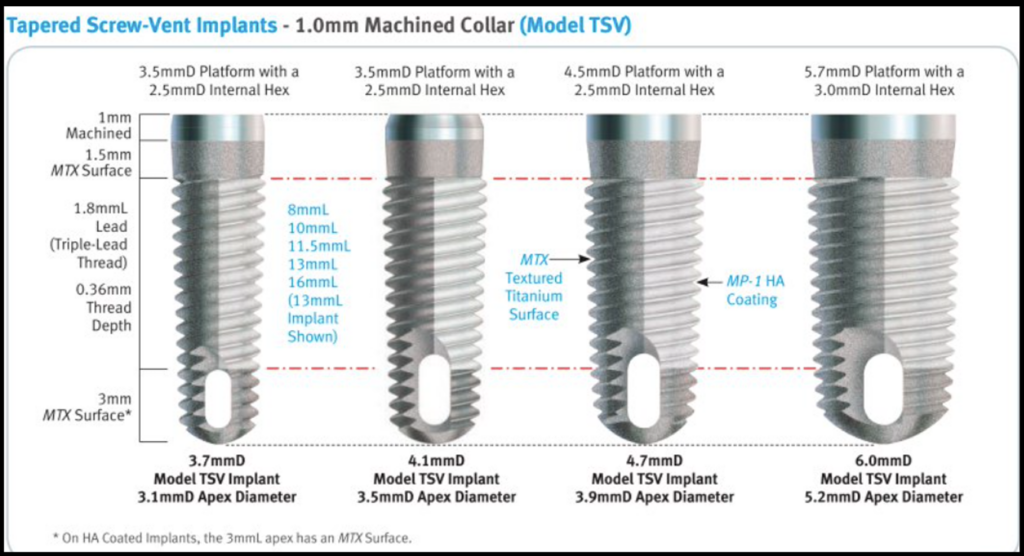

In 2010, ZimVie, to create a unique selling proposition, added a Trabecular Metal (“TM”) insert to the TSV, which, by 2012, triggered an FDA Recall. The threaded end of the implant repeatedly separated from the body of the implant when it engaged bone on full seating. The solution was to prepare the socket with a straight rather than step drill to prevent the threaded apex from engaging bone. As can be seen from the picture below from the ZimVie catalog, the TM implants are basically straight with a slightly tapered apex. The 3.7mmD implant has only a short section of Trabecular Metal while the wider implants have longer sections. Initial stability is enhanced by thread engagement and a tapered body. The U.S. list prices are: TM @ $550, TSX @ $540, TSV @ $507, Legacy2 @ $200.

ZimVie’s claims that the Trabecular Metal insertion on the Screw-Vent generates a “BioBoost Effect” that provides a “seemingly super natural multiplication of naturally occurring growth factors, delivering faster healing and earlier bone formation than traditional implants.” This is at best unproven and at worst pure sophistry. (definition sophistry — “the use of fallacious arguments, especially with the intention of deceiving”).

ZimVie Claims the following advantages of its TM Screw-Vent:

1. “Risk Management – Expanding treatment in poor bone.” The Tapered Screw-Vent’s soft bone surgical protocol addressed the risk of placing an implant in poor quality bone by undersizing the socket.

2. “Rapid Recovery – Accelerating healing with a 2-week final loading protocol.” Implants that achieve 30+Ncm of initial torque can be loaded immediately. Replacing half the length of the threads with a porous titanium mesh and using a straight rather than tapered implant detracts from initial stability and limits immediate loading success. Research has shown that stability of an implant decreases by week 2-4 following insertion but by week 7-8 its initial level is re-established. High initial stability makes initial reduction in stability irrelevant.

3. “Revision therapy – Leveraging the healing advantages in implant replacement.” Replacement of a failed implant requires establishing initial stability which is facilitated by greater thread engagement. ZimVie offers the HA coated TSV which could leverage the healing advantage.

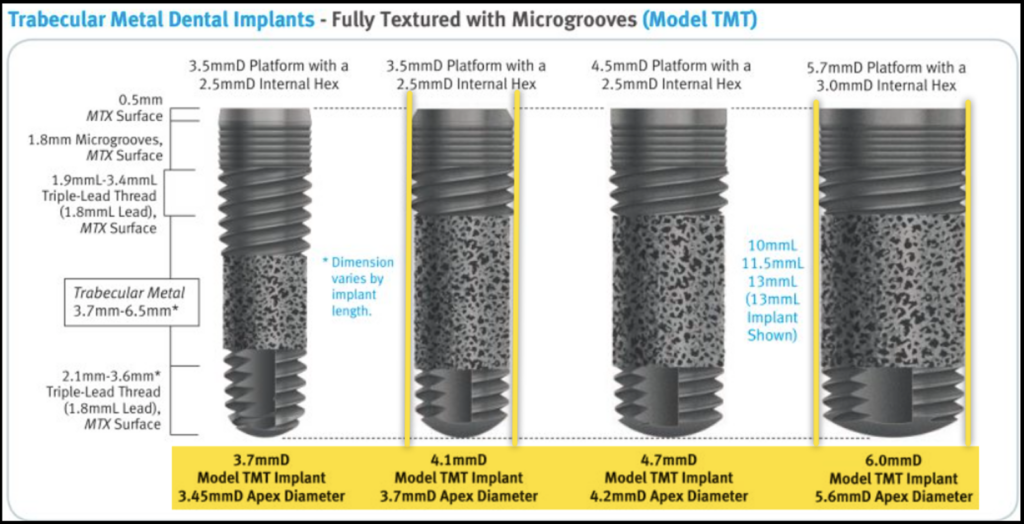

ZimVie’s Encode Scanning Healing Collars were recently updated to improve the emergence profile. Today, most companies offer reasonable priced scan adaptors which accomplish the same thing. Healing collars are of limited use with the increased popularity of immediate loading of overdenture, multi-unit & cementable abutments.

Analysis of the Shortcomings of ZimVie’s “Updated” Tapered Screw-Vent, Called TSX

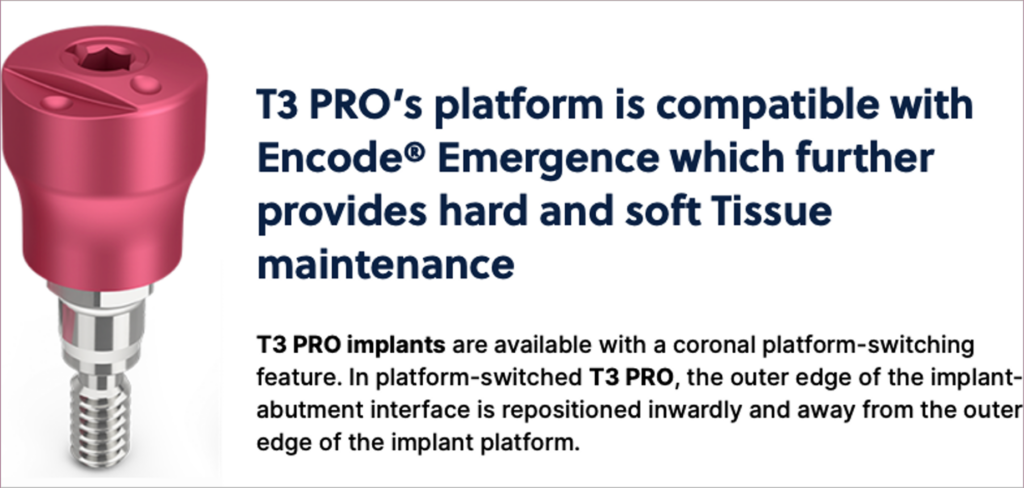

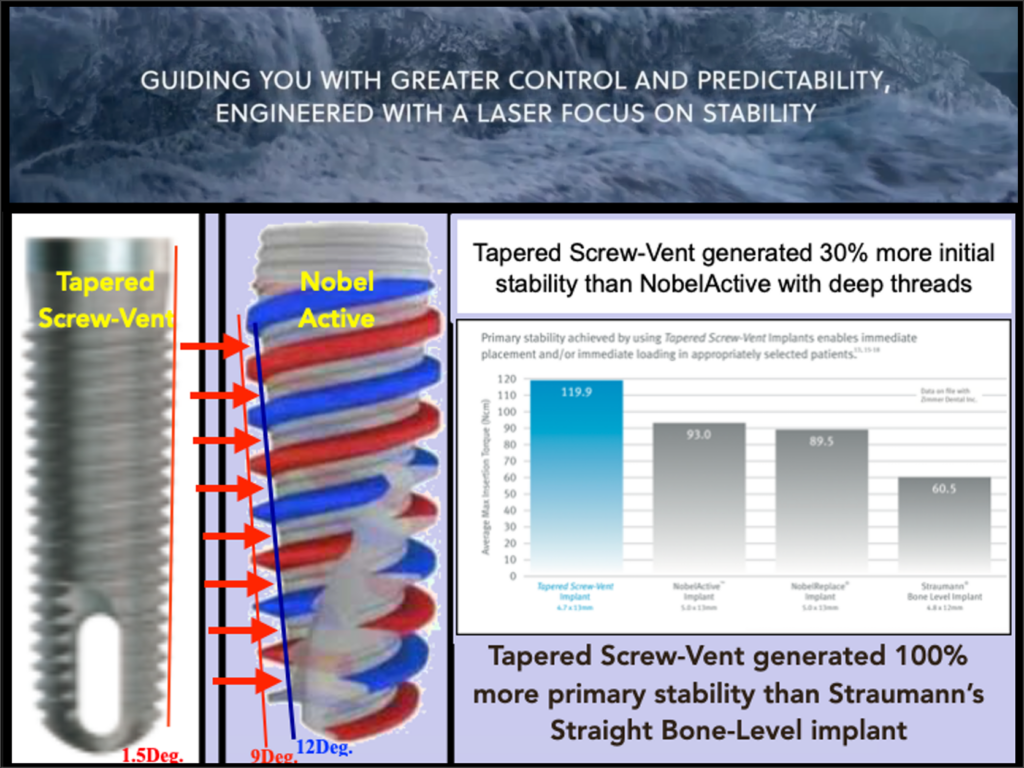

ZimVie’s website references a torque comparison study showing that the Tapered Screw-Vent (“TSV”), following the soft-bone surgical protocol developed for that implant in 1999, already achieves extremely high primary stability — 30% higher than the NobelActive and 100% higher than the straight Straumann TL implant.

In 2023 ZimVie launched the TSX Implant, claiming its Unique Selling Proposition was: “Going to the Xtreme for primary stability and peri-implant health.” The increased stability claim relates to adding progressively deeper threads. The initial stability is already extremely high with the TSV, created by inserting this tapered implant into an undersized socket. The claim of “peri-implant health” relates to the neck of the TSX implant being acid etched which is smoother than the rough, blasted surface BUT one option with the TSV is a 1mm machined neck which is smoother than an acid etched surface.

ZimVie’s US list price for the TSX is $540 vs $507 for the TSV. The difference of $33 is probably more than it costs to make either implant. Besides some cosmetic changes, the TSX adds bi-directional cutting grooves which can compromise stability by creating bone chips rather than compressing bone.

What is the difference between the TSX and TSV to justify the price increase?

With the TSX, …

(1) The threads get progressively deeper. Deep threads alone do not increase initial stability as shown by ZimVie’s comparison study between the TSV and NobelActive.

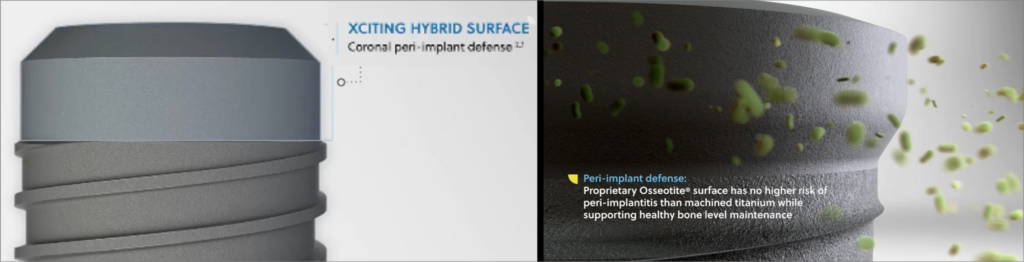

(2) The TSX replaces the smooth, machined neck of the TSV with an acid etched, textured surface that was on the body of the Certain 3i implant since 1996. ZimVie calls this surface Osseotite claiming it “has no higher risk of periimplantitis than machined titanium”. 3i/Zimmer Biomet/ ZimVie offered the Certain internal connection and external hex implants with a hybrid surface i.e. with an acid etched Osseotite surface on the body claiming it was rougher than the machined surface on the neck.

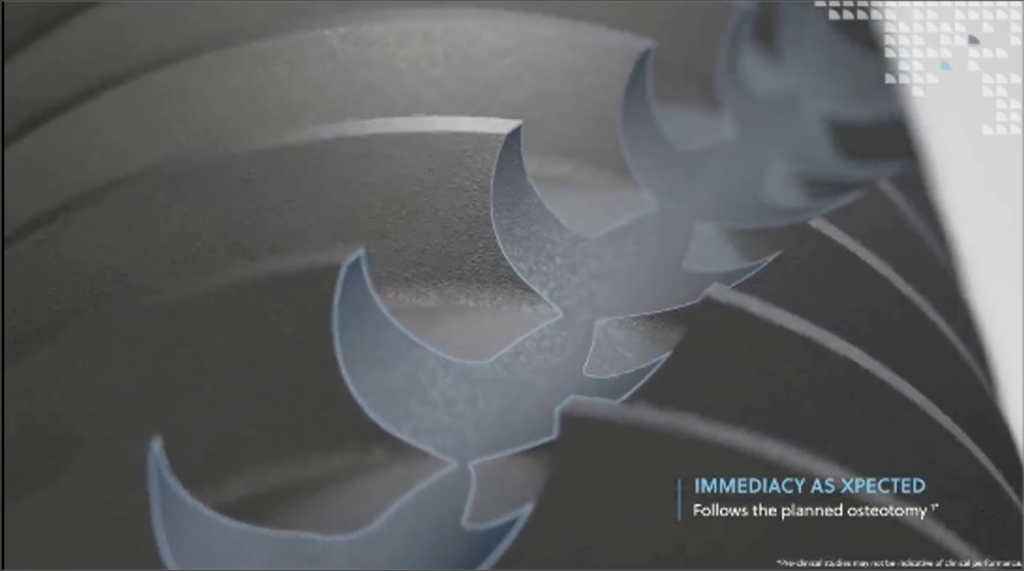

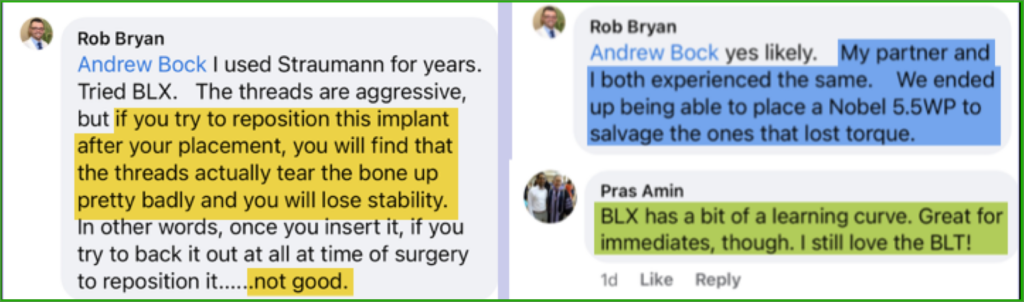

The cutting grooves changed from being vertical and only functioning in a clockwise rotation to being spiral with bi-directional cutting. This is a copy of Straumann’s BLX implant. Insertion of the BLX implant using a back-and-forth rotation as recommended for the BLX, will allow the counter-clockwise cutting grooves to widen the socket and will generate bone chips. Reports from dentists using the BLX are that if the implant is rotated counter-clockwise, it doesn’t just unscrew the implant, it will “tear the bone up pretty badly and you will lose stability”.

Bi-directional cutting grooves on the TSX and T3 PRO implants

The claw-like effect of the bi-directional cutting grooves of the BLX/TLX are designed to “Cut, Distribute, Condense and Collect” bone chips which can compromise initial stability… The surgical protocol of using this feature to overcome high insertion torque and allow full seating will decrease initial stability. Below are comments on LinkedIn from Dentists who experienced this dramatic reduction in stability.

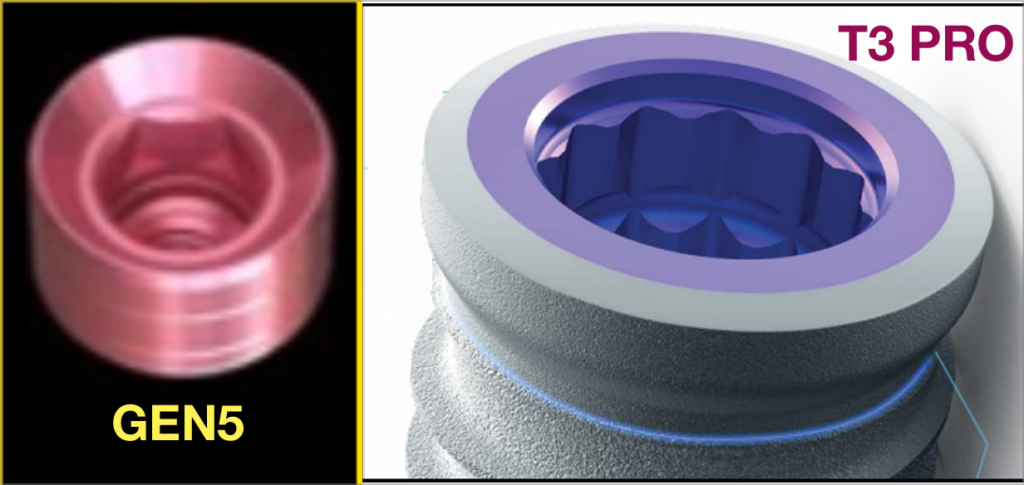

Analysis of the Marketing Claims of ZimVie’s Updated Certain Implant, Called T3 PRO

ZimVie claims that the T3 PRO is “Engineered with a laser focus on stability.” ZimVie modified its Certain Implant by adding the same progressively deeper threads and spiral, bi-directional cutting grooves as with the TSX. Achieving high (35+Ncm) intial stability in soft bone is accomplished by inserting a tapered implant into an undersized socket. ZimVie has demonstrated that the TSV provides 30% higher initial stability than the NobelActive with its deep threads and spiral cutting groove.

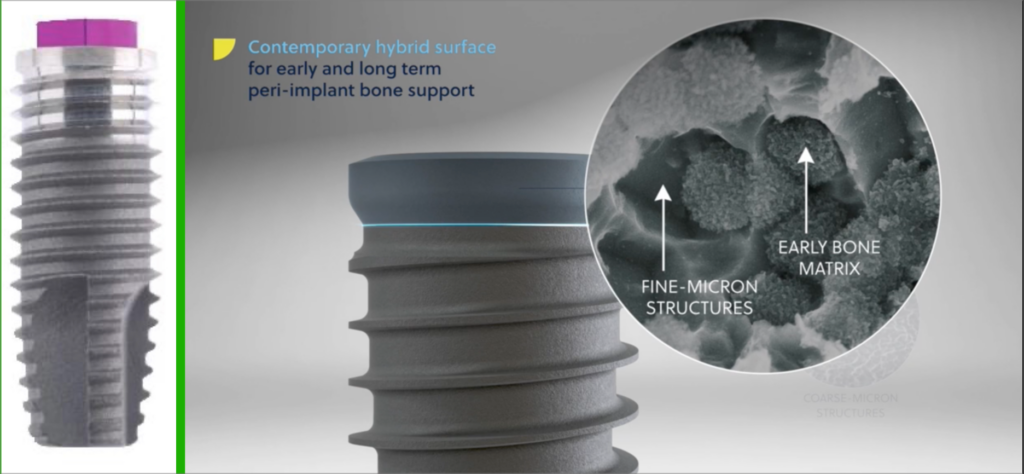

T3 PRO claims to have a “Contemporary hybrid surface.” The Osseotite® micropitted, acid-etched surface on the body of the Certain implant replaced the machined neck and a blasted surface replaced the Osseotite surface on the body. It is questionable whether the Osseotite on the neck is an advantage vs the machined surface.

T3 PRO tapers the inside thread diameter greater than the outside in order to make the thread depth progressively deeper towards the apex. Implant Direct’s Legacy implants made this change in 2008, 15 years ago. The implant In the yellow box is a GEN5™ with 2 vertical cutting grooves and progressive, buttress threads.

T3 PRO has spiral, bi-directional grooves with chisel. This is the same design as the Straumann BLX implant introduced in 2019 that generates bone chips rather than compressing the bone. The implant in the yellow box is a BLX with bone chips between the threads and in the grooves.

ZimVie claims “the foundation of T3 Pro remains the unique Certain connection … Better Seal Integrity than Conical and Other Flat-on-Flat Connections.” It is a widely accepted that conical connections provide greater stability and seal than flat-on-flat connections.

EVOLUTION AND INNOVATION: THREE PATENTED FEATURES OF THE GEN5™ AND GEN5+™ IMPLANTS

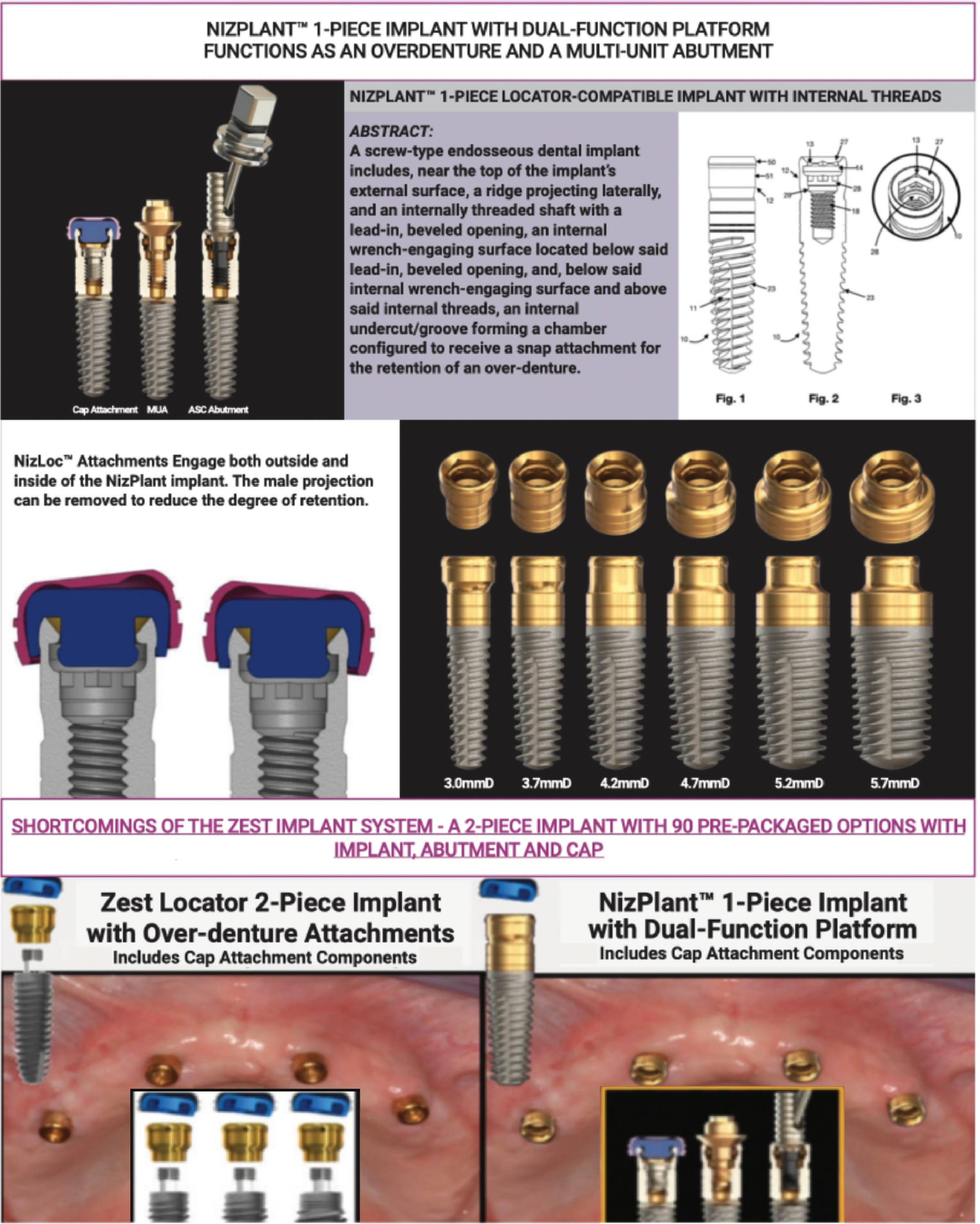

PATENTED FEATURES OF THE 1-PIECE NIZPLANT™ IMPLANT WITH ITS DUAL-FUNCTION PLATFORM

Related Posts

Our Mission is to provide high-quality state-of-the-art dental implants and abutments through internet sales at factory-direct prices.

GET TO KNOW US

LET US HELP YOU

STAY CONNECTED

- Contact Us

- info@paragon-implant.com

- 855.NIZ.GEN5

- Mon-Fri 6am-5pm PST