- Controversial issues that affect the dental implant dentistry

Analysis Of The Shortcomings Of The Megagen™ Implant System

- Gerald Niznick

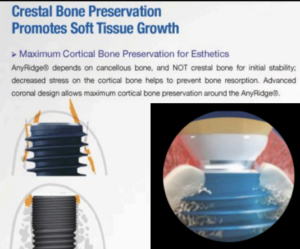

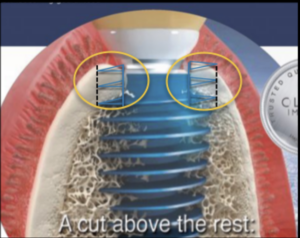

The Megagen Implant claims to be “A cut above the rest”. A better description woud be “A cut through the crest”. The Megagen implants do not have vertical cutting grooves. As can be seen from the yellow circles with the path of the threads superimposed over the cortical bone, Megagen’s fin-like threads will expand the cortical bone as it is threaded to place, creating a gap around the narrow neck of the implant that could allow down-growth of soft tissue, creating an infra-bony pocket. Studies show that engaging the cortical bone adds significantly to the initial stability.

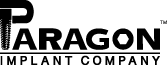

Megagen claims that its AnyRidge design with threads wider than the neck of the implant will preserve crestal bone by eliminating initial contact of the narrow neck with the crestal cortical bone. “Megagen’s AnyRidge implant depends on cancellous bone, and NOT Crestal bone for initial stability.” This is wrong-headed thinking. It is long proven and well-understood that engagement of cortical bone by an endosseous implant assures stability.

This case shows 16 Legacy implants placed level with the crest of the ridge with no bone loss evident at uncovering. Megagen’s design with a narrow neck and wide, deep threads for “maximum cortical bone preservation” is based on this false premise which unnecessarily sacrifices initial stability. If there is concern about high insertion torque in dense bone negatively affecting the cortical bone, then just use a crestal bone drill to open up the socket to the full diameter of the neck of the implant. insertion of a 5.5mmD implant, leaving an opening for the down growth of soft tissue. 5.5mmD implant leaving an opening for the down-growth of soft tissue–,

Megagen sells Cortical Bone Drills to facilitate insertion of the wide threads. The sharp threads may be self-threading in soft bone but it is not self-tapping in dense bone, especially through the cortical bone at the crest of the ridge. As you can see from the graphic below, a cortical bone drill of 4.8mmD is available to create the opening through the cortical bone for the insertion of a 5.5mmD implant, leaving an opening for the down-growth of soft tissue

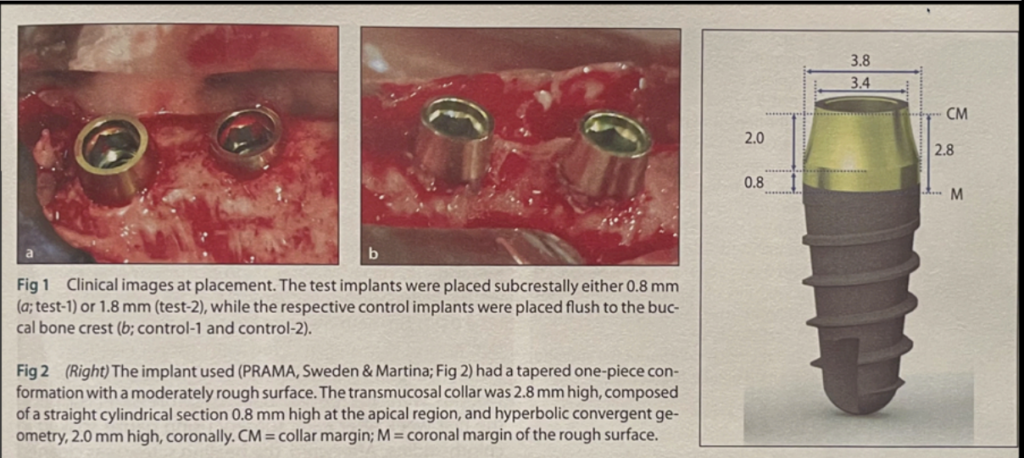

This study compared subcrestal positioning of the implant concave neck with the placement of the widest part of the implant level with the crest, sealing the opening. It concluded: “The placement of implants with a hyperbolic convergent profile collar in the subcrestal position resulted in higher buccal bone resorption and more soft tissue recession.”

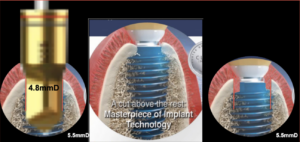

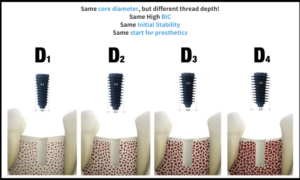

Megagen uses the same Platform and same inner core of the implant for implant diameters from 3.5mmD to 5.5mmD and the thread diameter increases. The theory behind the design is that the thread depth increases as the density of the bone decreases. This is in contrast to most other implant companies insertion protocol for a tapered implant. They follow a soft-bone/hard bone surgical concept first published by Niznick 2000, that varies the diameter of the final drill based on the density of the bone. To achieve insertion in dense bone without use of a bone tap by preparing a socket almost as wide as the diameter of the implant. That way, only the tips of the threads engage dense bone and full seating can be achieved. In soft bone the final drill undersizes the socket so that insertion compresses the bone and increases its density and the stability of the implant.

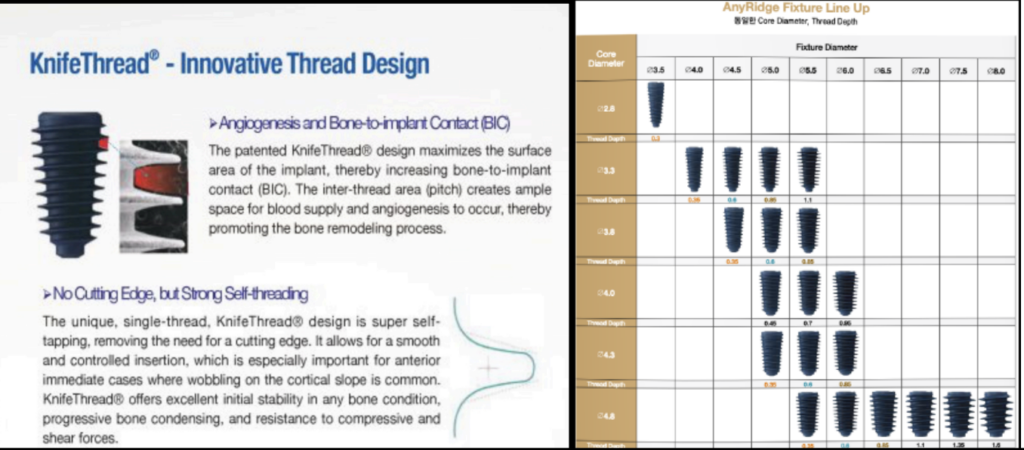

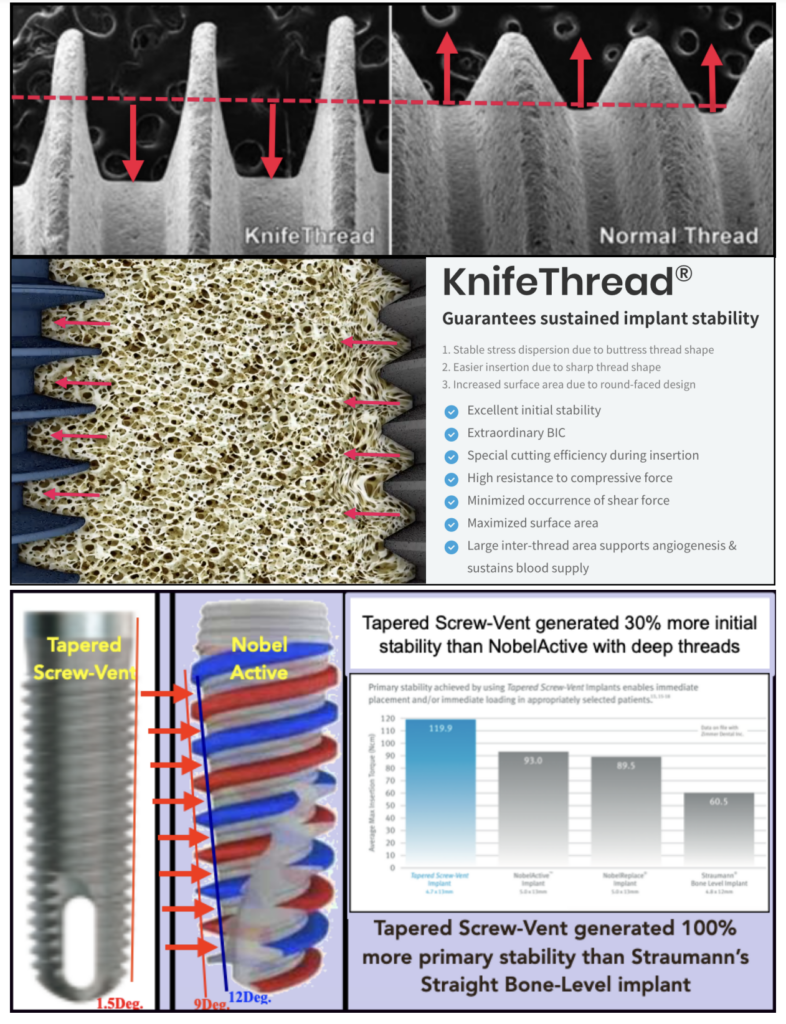

The depth of the Megagen KnifeThread varies with the diameter of the implant. In soft bone, deep threads leave space for the soft bone to be compressed into rather than compressing the soft bone. In dense bone, without a bone tap or self-tapping grooves, only the tips of the threads can engage bone, reducing the initial stability achieved with self-tapping threads.

Megagen implant design is based on the theory that deep, knife edged threads will cut their way into bone without the need for a self-cutting groove or a bone tape, and will increase initial stability and ultimately surface area. The fallacy in this logic is that increased stability in soft bone is achieved by compressing the bone to improve its quality (the whole theory behind the popular Densah drill system). In fact, as proven in a comparative study by ZimVie between the Tapered Screw-Vent (TSV) and the NobelActive with deeper threads, the TSV generated 120Ncm of initial torque compared to 93Ncm with the NobelActive because its deep threads created a space for the soft bone to move into rather than being compressed.

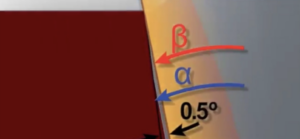

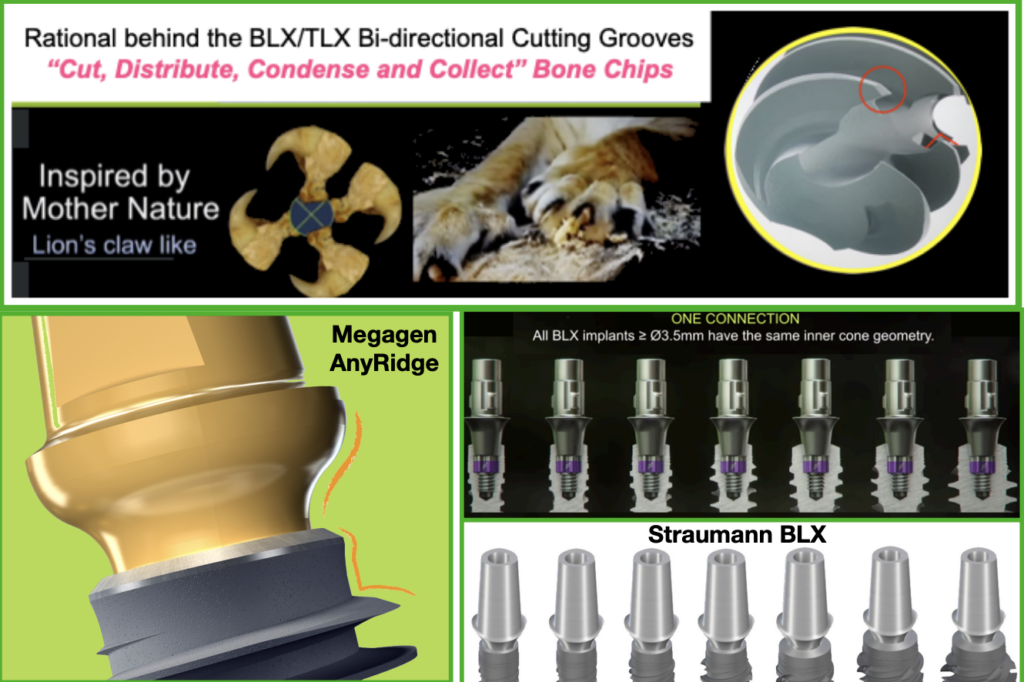

The Megagen Conical Connection is at 5 degree from the vertical. For conical connections to be effective at sealing the opening to the internal shaft, the mating abutment bevel needs to be 0.5-1.0 degrees greater as measured from the vertical so that the first contact is at the opening of the shaft. This drawing is not representative of an actual implant-abutment connection. This drawing from the Keystone Paltop implant more accurately represents how an abutment interfaces with a conical connection and demonstrates why steeper angled interfaces do not add to the contact area and therefore to the stability.

Megagen’s AnyRidge implants are available in diameters ranging from 3.5mmD to 8mmD as measured to the outside diameter of the threads. The neck and core diameters remain the same for implants 3.5mmD through 5.5mmD but increase in size with the 6.0mmD to 8.0mmD implants. All Megagen AnyRidge implants have the same implant/abutment interface. Using a single platform over this wide a range of implant diameters compromises the emergence profile and provide questionable strength with the use of the same small neck diameter of abutment is used on the 3.5mmD implant in the esthetic zone as the 8mmD implant recommended for molar restorations. As can be seen below (L), use of a single abutment platform is not conducive for a natural emergence profile and the abutments for cementable restoration do not have a contoured margin. If recession takes place and the margin of the pre-parable abutment needs to be lowered, the steep undercut below the abutment’s height of contour will not allow such adjustments.

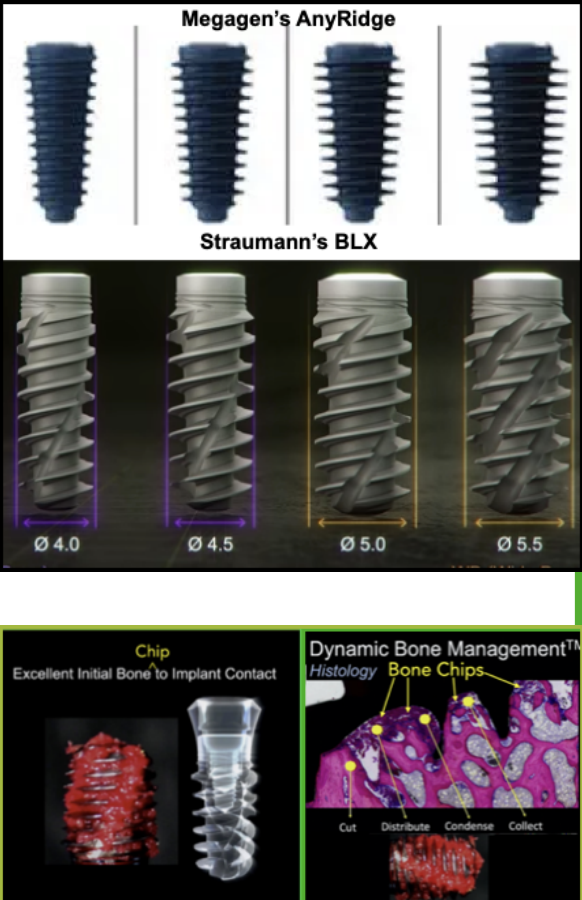

The BLX from Straumann, introduced in 2019, follows a similar concept and design to the Megagen AnyRidge Implant. For implants 3.5mmD to 5.5mmD, the diameter of the threads increases without any corresponding increase in the diameter of the necks. The result is that in soft bone, the threads expand the crestal opening and in dense bone, a large diameter drill is needed to open the socket to accommodate the wide threads. In either situation, a gap is created at the opening with a loss of contact with cortical bone. Both systems offer a single conical connection, Straumann’s being 7 degrees while Megagen’s 5 degrees. This creates an undesirable emergence profile as the width of the exposed shoulder increases with each diameter of the implants. The implants differ in that the AnyRidge implant does not have a self-tapping cutting groove whereas the BLX, which unlike the AnyRidge, is basically a straight implant for the first 12mm, has bi-directional cutting grooves that create bone chips in soft bone rather than compressing the bone contribute to stability. Both systems compromise initial stability due to the narrow necks not engaging cortical bone and the deep threads creating room for bone chips rather than compressing soft bone.

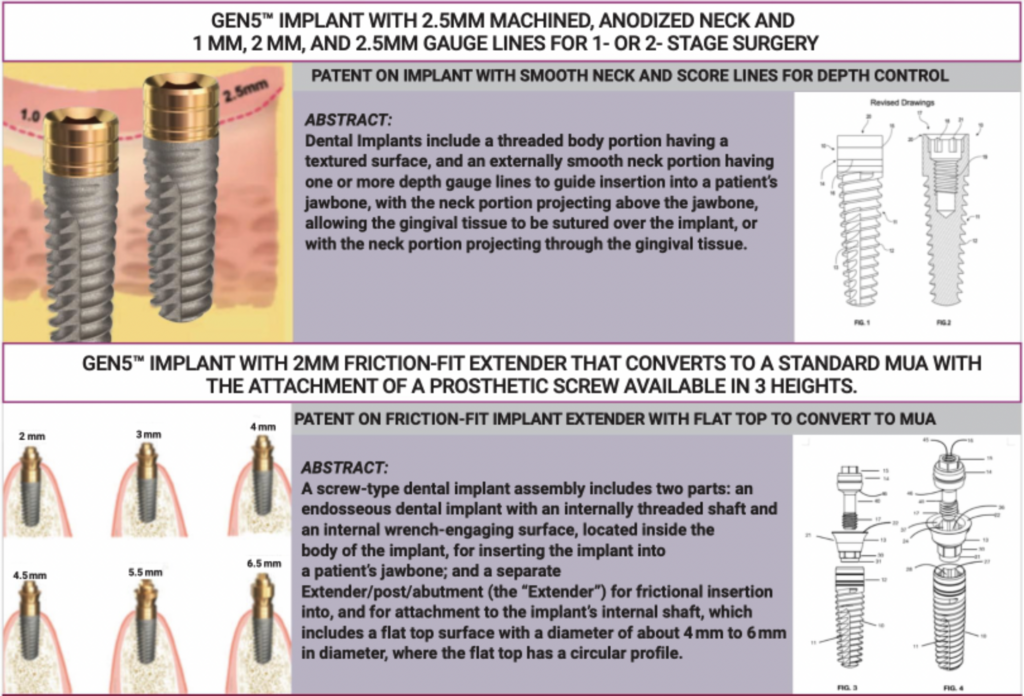

EVOLUTION AND INNOVATION: THREE PATENTED FEATURES OF THE GEN5™ AND GEN5+™ IMPLANTS

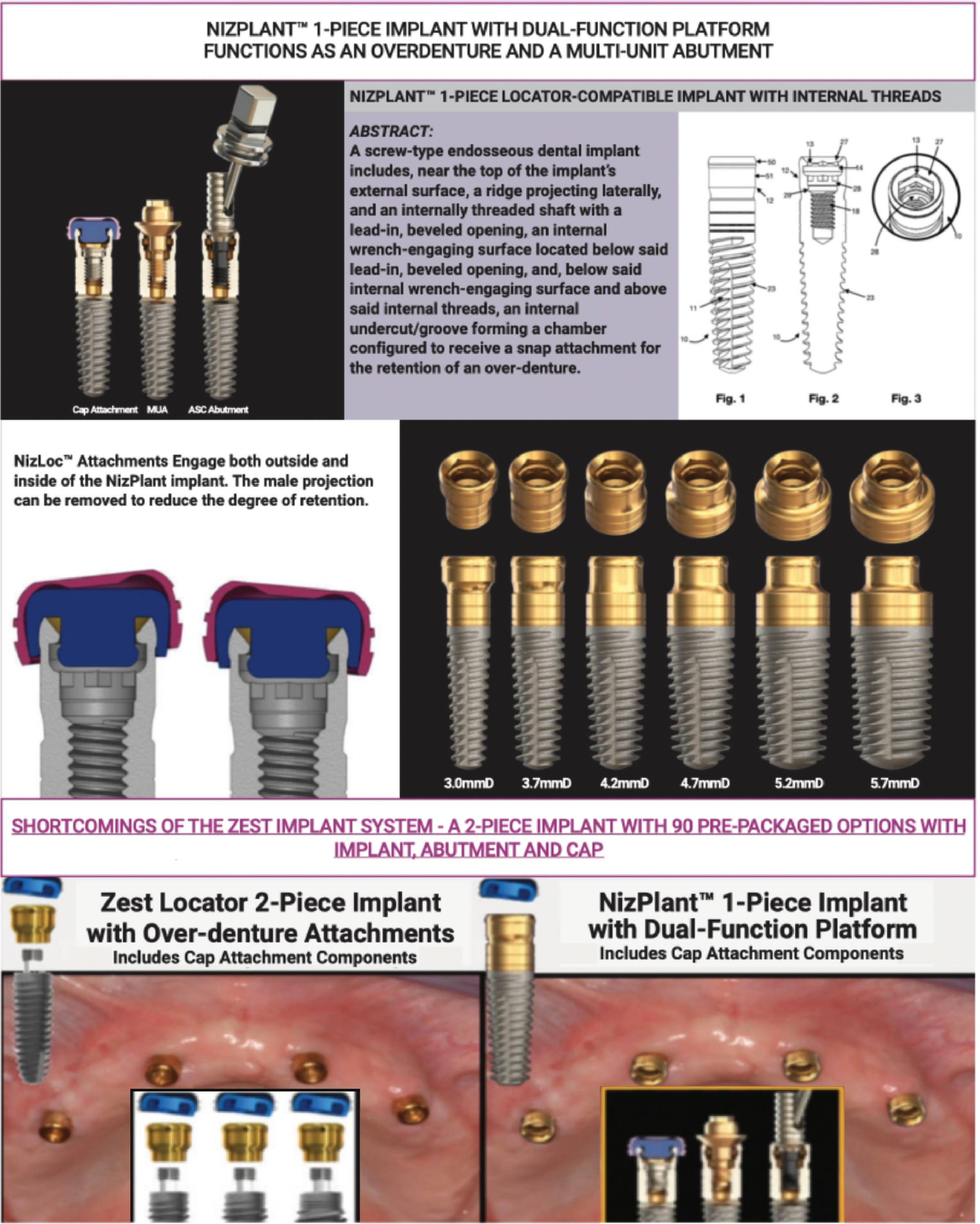

PATENTED FEATURES OF THE 1-PIECE NIZPLANT™ IMPLANT WITH ITS DUAL-FUNCTION PLATFORM

Related Posts

Our mission is to provide high-quality, innovative, dental implants and abutments through internet sales at factory-direct prices.

GET TO KNOW US

LET US HELP YOU

STAY CONNECTED

- Contact Us

- info@paragon-implant.com

- 855.NIZ.GEN5

- Mon-Fri 6am-5pm PST