Implant Industry Newsletter Volume 1

Implant Industry Newsletter Volume 1

This newsletter addresses these three controversial topics:

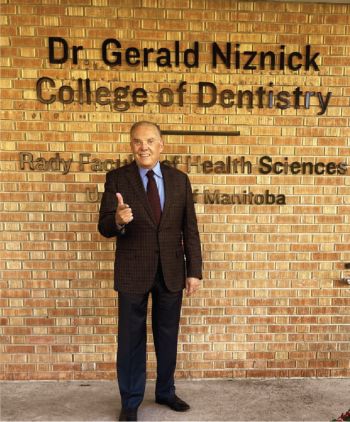

Gerald Niznick DMD, MSD is a prosthodontist who was the founder and president of four implant companies over the last 42 years: Core-Vent (1982-1997), Paragon (1997-2001), Implant Direct® (2004-2013) and the new Paragon™ (2022-present). Dr. Niznick has been awarded 33 US Patents, including the internal conical connection (1987) that has become the cornerstone of modern implant design. As of the date of this newsletter, he has four pending patent applications related to design features of Paragon’s™ new implant system. Dr. Niznick has been at the forefront of the evolution of implant design and has been addressing the controversies created by competing implant claims for over 40 years. For more information on Dr. Niznick and the dental implant industry history, visit www.paragon-implant.com.

Dear Colleagues,

This is the first edition of a series of newsletters I will write and circulate to dentists interested in dental implants. Regardless which implant system(s) you are currently using, the general information provided in these newsletters, along with the links to videos and articles, will broaden your knowledge and help you make informed decisions regarding products and procedures.

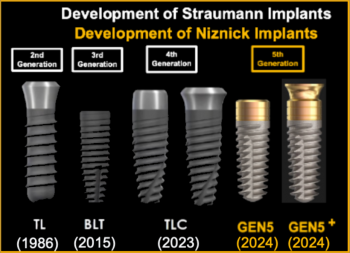

In 1982, I launched the Core-Vent Implant System, which I consider Generation 1 of modern dental implants, since it was the first implant system to offer a variety of application-specific abutments. In 1986, I launched the Screw-Vent (Generation 2) with the industry’s first conical connection. In 1999, I launched the Tapered Screw-Vent (“TSV®” – Generation 3), improving initial stability in soft bone. I sold Core-Vent Corp. in 2000, to what today is ZimVie. In 2004 I started Implant Direct®, credited with starting the Value Segment of the implant industry, because of its All-in-1 packaging and online ordering. Implant Direct launched the tapered Legacy implant (Generation 4) in 2008 with micro-threads and progressively deeper body threads. Since 1986, all of these implants had the same internal hex, conical connection with a 45 degree lead-in bevel that I received a patent on in 1990.

In the fall of 2024, Paragon will launch the 5th generation of implants, covered by several new patents. These Simply Smarter™ designs will redefine “Value” and “Premium” for dental implants. I hope the information herein provides you with valuable insights and furthers your understanding of the industry and implant design rationale.

Sincerely,

Dr. Gerald Niznick, DMD, MSD

Sub- vs Supra-Crestal Implant Placement

One of the most debated controversies in Implant Dentistry relates to the position of the top of the implant relative to the crest of the ridge. The surgical protocol for the Core-Vent implant, launched in 1982, was to place the implant 1mm supra-crestal. The implant lengths were 1mm longer than the corresponding score lines on the drills. This was done to make it easier to palpate through the tissue to locate and then uncover the implant.

Prof. Daniel Buser, former ITI President, describes his preferred method of placing part of the 2.8mm smooth neck of the Straumann® TL implants, sub-crestal. It was not until 2007 that Straumann introduced its Bone Level (“BL”) implant which, in 2015, was offered in a tapered version (BLT®). Straumann introduced the BLX and TLX relatively straight implants, with very aggressive threads in 2019 & 2021, and the newest addition to its product line, TLC in 2023. Paragon™ is set to launch its GEN5™ and GEN5+™ implants in 2024.

Buser Quote on Straumann’s Website:

“The Future of Implant Dentistry is with the neck designs combining a smooth surface in the trans-mucosal area with a micro-rough

inside the bone”

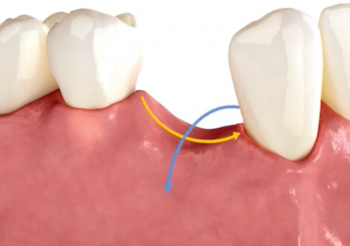

Most ridges, especially with immediate placement in extraction sockets, are seldom level. Hybrid design surfaces, with a smooth 2mm-3mm neck, allow placement level with the highest point of the ridge, usually on the lingual, without exposing the rough surface of the implant to the soft tissue on the labial/buccal. Placing the implant supra-crestal distances the implant-abutment junction from the bone and provides a zone of undisturbed soft tissue attachment. |

Paragon’s GEN5 implants have a 2.5mm smooth, anodized neck with score lines at 1mm, 2mm and 2.5mm. Each implant length has an additional 1mm added compared to the standard lengths for the Screw-Vent and Legacy implants. This allows placement level with or 1mm supra-crestal, depending on which drill stop is selected. The drill stops do not rotate with the drill, allowing them to be inserted through sleeves in the surgical guides. This eliminates the need for keys to guide the drills, or length specific drills with hubs that fit into the guide sleeves.

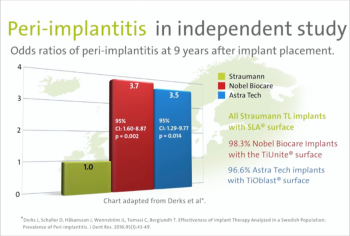

Dr. Niznick Article: AO News Vol.33 No. 2, 2022: “Dr. Buser cites a Swedish 10-year study comparing three implants: Astra, NobelBiocare™ and Straumann’s Tissue Level implant, claiming the latter exhibited significantly less peri-implantitis. Assuming part of the smooth neck of the Straumann TL implant was inserted in bone, this would give it a hybrid bone interface. It also adds the variable that the implant-abutment connection would be supra-crestal… [which] is at least as important a factor in minimizing peri-implantitis as a hybrid surface.”

Study showed more bone loss with sub-crestal compared to supra-crestal placement

“This case study measured early crestal bone changes around sub-crestal placed platform-switched implants surrounded by thin soft tissue and compared them with regular, matching-platform implants placed in a supra-crestal position and surrounded by thick soft tissue. After 1 year, average bone loss was 0.28mm with the supra-crestal vs 0.6mm with the sub-crestal implants.”

45° Conical Hex Connections

This case of two Straumann BLT implants placed sub-crestal shows that the bone contact will recede to below the implant-abutment junction, sacrificing several millimeters of bone support and creating a deep gingival crevice that ensures a 4+mm pocket. By contrast, the image on the right demonstrates the positioning of 2 GEN5 implants level with or 1mm supra-crestal, which will result in the implant abutment junction being 1-2mm sub-gingival, facilitating scanning or impression procedures, and resulting in a shallow pocket around the implants that can better be hygienically maintained.

Sub-crestal placement reduces primary stability… and often requires countersinking

Implant Abutment Connection

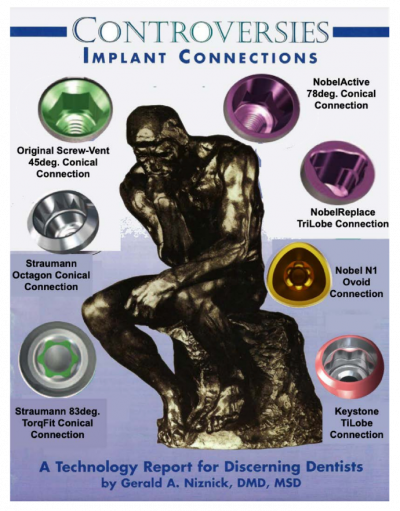

In 1986 Core-Vent Corp. introduced the Screw-Vent with the first internal conical connection (45° lead-in bevel above an internal hex wrench-engaging surface). This patent became the cornerstone for future implant designs. Straumann, Friadent and Calcitek were among the companies that took a license under the Niznick 4,960,381 US Patent. In 2008, after the Niznick ‘381 patent expired, NobelBiocare acquired Alpha-Bio Tec, an Israeli company, and launched NobelActive® with its 78° lead-in bevel and internal hex. Stability with internal conical connections is achieved by making the mating angle of the abutment 0.5°-1° less, as measured from the vertical axis of the implant, to assure the primary contact will be at the opening to the internal shaft. Steeper lead-in bevels with conical connections do little if anything to increase stability.

A study comparing 3 year post loading outcomes of implants with 45° vs 78° lead-in bevels from the same manufacturer concluded: “no statistically significant differences in marginal bone remodeling or complications (including implant/ prosthesis failure) between implants with IH connections (Internal hex > 45° bevel) and those with IC connections (internal slots > 78° bevel) connections 3 years after loading.

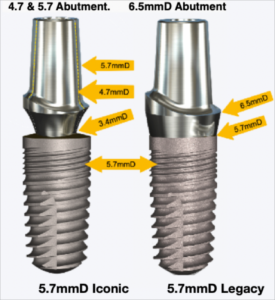

In 2013, Implant Direct Sybron launched the InterActive® implant with a NobelActive compatible platform and received FDA clearance to claim prosthetic compatibility, but after Implant Direct’s parent company (now called Envista) acquired NobelBiocare, Implant Direct removed all reference to prosthetic compatibility from its marketing materials. In 2023, Implant Direct launched the “Simply Iconic®” implant with the InterActive (NobelActive) prosthetic connection. The Iconic is a combination of the Legacy implant body and the InterActive/NobelActive connection. The mismatch creates emergence profile problems and thins the walls of the narrower implants, increasing risk of fracture.

Straumann’s implant systems contribute to “Connection Confusion”.

1. “Nuvo™” implant with standard 45° lead-in bevel

2. Neodent® “Grand Morse®” connection = 74° lead-in bevel

3. Straumann’s “CrossFit” connection = 75° lead-in bevel

4. Straumann’s “synOcta®” connection = 82° lead-in bevel

5. Straumann’s “TorcFit™” BLX/TLX connection = 83° lead-in bevel

6. Neodent’s new “Helix Short” implant with a 45° lead-in bevel

Straumann’s BLX implants offer only one connection diameter, claiming simplicity, but it compromises emergence profile. To compensate for this limitation, Straumann makes wider abutments that overlaps the shoulder…BUT this means that the only contact is on the shoulder, not on the lead-in bevel, compromising stability.

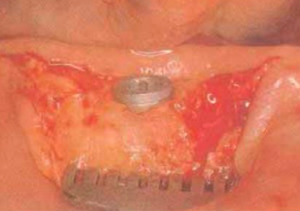

Treatment & Prevention of Peri-implantitis

With the increased use of dental implants, the incidence of short and long-term complications have increased: A study entitled “Zeroing in on Zero Complications” showed the 5-year implant survival rate was 94%-95% and the 16-year implant survival rate was 82.9% with 48.03% of total complications: 16.94% Biological and 31.09% Technical.

- Here is a video showing how the “Impact™” drill smooths the surface and debrides the socket at the same time.

- The GalvoSurge™ device, recently acquired by Straumann, effectively removes bacterial biofilm from dental implants affected by peri-implantitis. It accomplishes this by the introduction of electrolysis to clean and decontaminate affected dental implants. The exposed implant surface will reform bacterial biofilm unless it is smoothed.

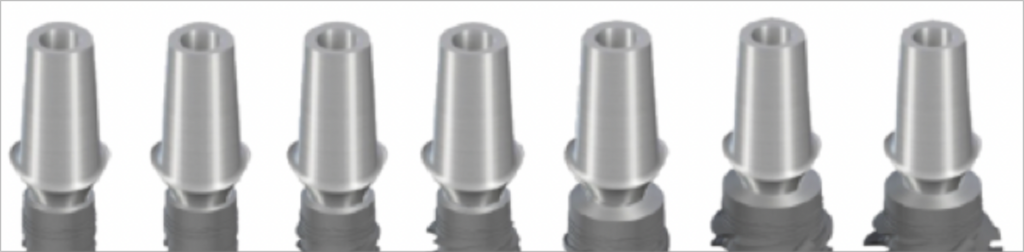

As the saying goes, “an ounce of prevention is worth a pound of cure”, so it would be logical to start out with a relatively smooth neck. The picture shows ZimVie’s Tapered Screw-Vent (Niznick 1999) along with its new TSX implant, Implant Direct’s Legacy (Niznick 2007) along with its new Iconic implant, and Paragon’s GEN5 and GEN5+ (Niznick 2024) implants with a 2.5mm smooth anodized neck. The Paragon implants add an additional 1mm to the standard lengths to give the dentist the option of placing the implant 1mm supra-crestal.

3D Video explaining the cause, treatment and prevention of peri-implantitis While roughened surfaces are advantageous for osseointegration, they are also very prone to bacterial colonization. Bone remodeling causing the lower endosseous rough part of the implant to be exposed to the oral cavity, creates an environment that may lead to peri-implantitis. |

Prof. Buser, former ITI President, describes the evolution of the Straumann Hybrid surface implant and how he has used it since the mid 1990’s by pushing part of the smooth neck sub-crestal. |

Articles on the benefits of hybrid designed implant surfaces on preventing peri-implantitis were featured in 2023 Academy of Osseointegration Newsletters. Three of the implant design factors that have been shown to reduce the incidence of peri-implantitis are (1) a smooth neck, (2) supra-crestal positioning of the implant-abutment junction and (3) stability of implant-abutment junction.

Complete Your Profile

Receive priority access to our pre-launch product portfolio, lecture information, and any pre-launch product specials.

Our mission is to provide high-quality, innovative, dental implants and abutments through internet sales at factory-direct prices.

GET TO KNOW US

LET US HELP YOU

STAY CONNECTED

- Contact Us

- info@paragon-implant.com

- 855.NIZ.GEN5

- Mon-Fri 6am-5pm PST