Controversial Issues that Effect the Dental Implant Industry

Shortcomings of Straumann's® Bone-Level Implants in Contrast to Paragon's TriFit™ Implant

December 5, 2024 | Dr. Gerald Niznick

Share this Post:

Evolution of Straumann® Implants

Straumann pioneered Tissue Level (“TL”) implants 1980’s – 1990’s that eliminated the need for a second surgical procedure but had limitations in the esthetic zone. In 2007 Straumann introduced its first Bonelevel(“BL”) implant in the form of a straight, bullet shaped implant. In 2015, Straumann introduced its first tapered bone-level (’BLT”) implant, 16 years after Core-Vent introduced its Tapered Screw-Vent® (TSV) currently being sold by Zimvie®. The TSV starts its taper a few millimeters from the top to achieve increased initial stability by gentle expansion/compression of soft bone. Straumann’s BLT, by contrast, has an overall straight body with only the apical 5mm being tapered.

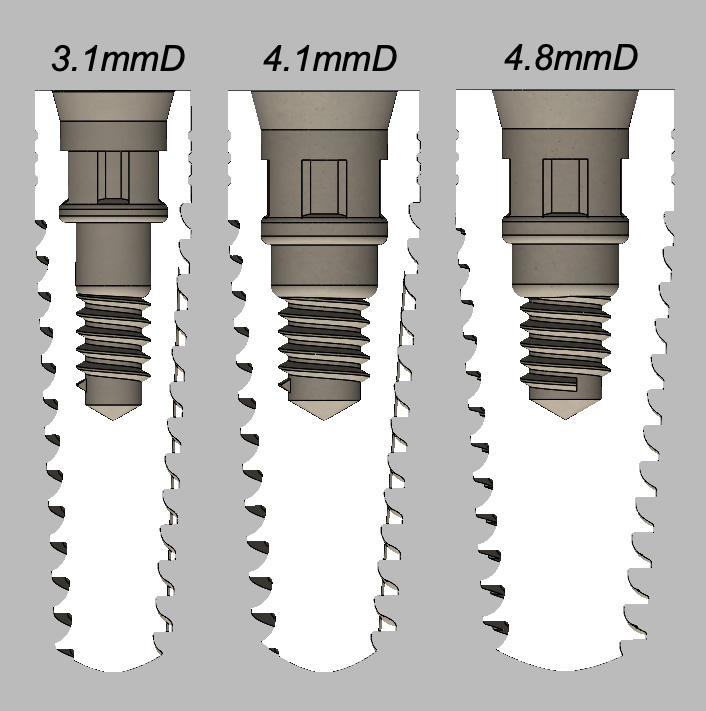

Straumann’s BLT has become its flagship implant, it comes in 4 diameters with 3 different platform dimensions. The difference between the 3.3mmD implant and the 2.9mmD implant is 0.4mm or 0.2mm on each side. This is the thickness of the upper limit of a human hair so it hardly justifies the need for a 2.9mmD BLT which requires a smaller diameter internal connection and a different set of abutments.

Straumann Bone-Level Tapered Implants with CrossFit Connection

Predominant design shortcomings of the BLT implants are:

- The implant is straight for the majority of its length with only the apical 5mm tapered.

- The threads and blasted surface run up to the top of the implant, risking exposure.

- The threads are not progressively deeper apically for increased surface area and stability.

- The depth of the internal CrossFit® connection is 4.6mm – too deep to allow 6mm implant.

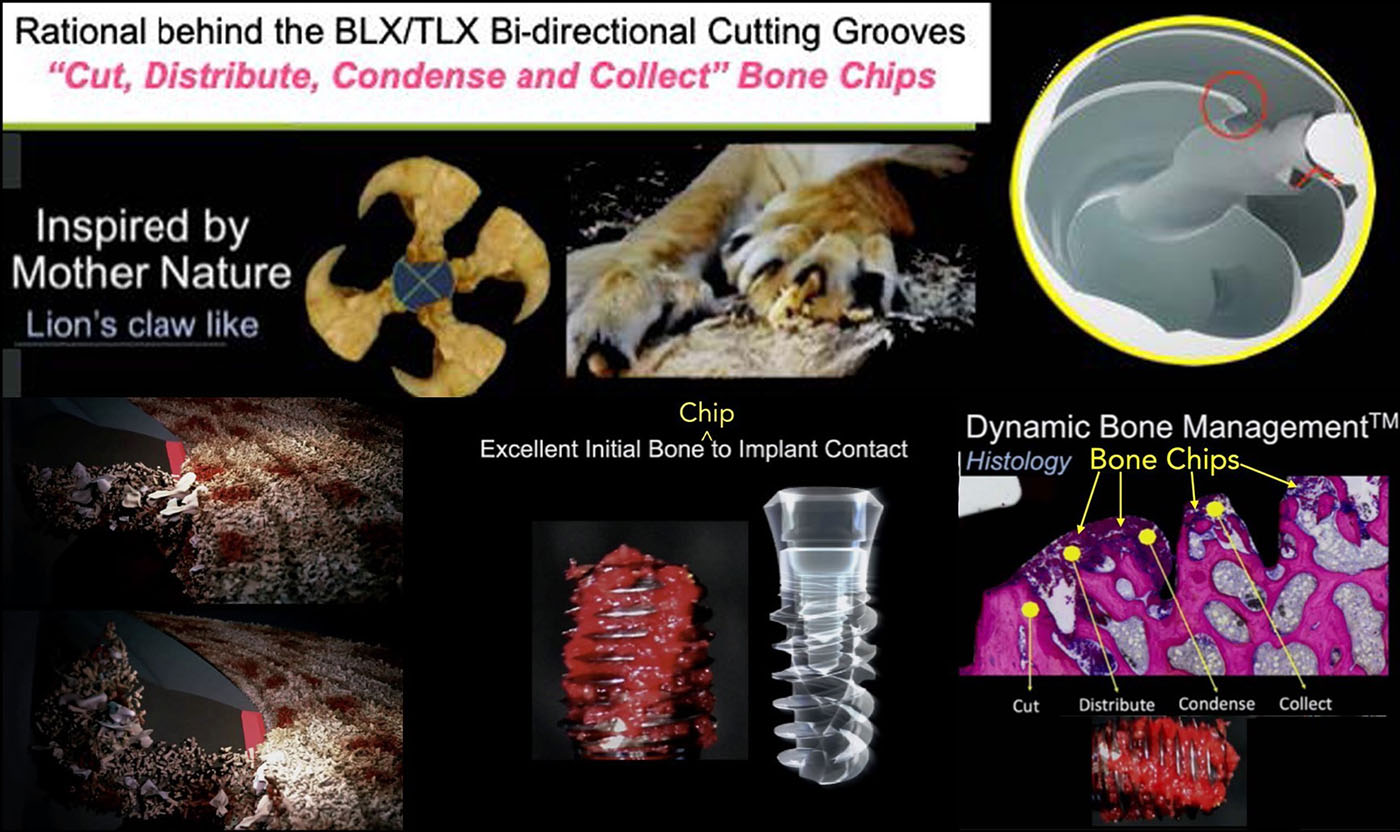

In 2019 Straumann introduced the BLX implant claiming that its deep threads made it well suited for immediate load applications. It refers to the BLX as a “Fully Tapered Implant” when in fact, the implant is straight for all implants 12mm and shorter, with longer implants having a tapered apex. The implant has progressively deeper threads created by the very tapered inner core of the threads. It also has bi- directional cutting grooves designed to “Cut, Distribute, Condense and Collect” bone Chips.

A study demonstrated that the NobelActive’s® deeper threads did not create as high an insertion torque as the shallower threads of the Tapered Screw- Vent. When placing a tapered implant into an undersized socket in soft bone, deep threads create space for soft bone to flow into, whereas contact with the inner core, compresses the bone.

Straumann’s recommended surgical protocol is to not exceed 50Ncm on insertion and to turn the implant counterclockwise to allow the BLX’s bi-directional, spiral cutting grooves to shave bone to reduce the insertion torque. Bone chips can be seen in the histology below, between the implant surface and the bone. Increased initial stability in soft bone is related to compressing the bone.

MISCONCEPTION – Bone chips contribute to increased stability:

The spiral sluiceways of the “claw like” bi-directional cutting grooves create bone chips that are deposited in the deep threads and sluiceways. This Video from Dr. Fromovich’s lecture(Developer of BLX), shows bone chips being expelled from the surgical site on insertion (1, 2 & 3) and on removal of the implant from the surgical site (4).

MISCONCEPTION – 1 Platform offers clinical advantages:

Straumann claims that by using only one connection for all the diameters of BLX implants, they have “Simplified Workflow [and] Reduced inventory.” While it is true that only having one connection would reduce the inventory of abutment and transfer components, this has nothing to do with a “Simplified Workflow.” Only having 1 platform diameter for 7 implant diameters limited strength of abutments and compromises emergence profile on the wider implants.

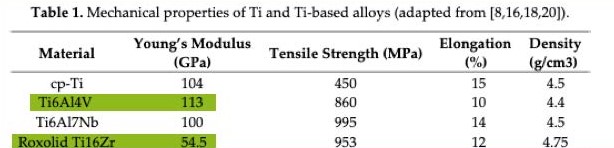

MISCONCEPTION – Roxolid titanium alloy offers advantages over Ti6Al4V alloy.

Straumann’s implants are made from an alloy of Titanium and Zirconium, which they call Roxolid®. Most other implant companies use Ti6Al4V alloy which has a modulus of elasticity more than twice that of Ti16Zr and therefore, is less brittle.

“Young’s modulus is a measure of the ability of a material to withstand changes in length when under lengthwise tension or compression. Sometimes referred to as the modulus of elasticity, Young’s modulus is equal to the longitudinal stress divided by the strain.”

MISCONCEPTION – Seating a wide abutment on the shoulder of the implant to overcome innate emergence profile limitations:

Straumann offers a wider abutment option for the 3 widest implants, that seats on part of the implant’s shoulder.

Straumann claims its TorcFit is a hybrid connection that can interface with either the internal 7 degree cone or the shoulder of the implant. As shown below, the wider abutments only make contact on its periphery. Abutments that seat on the top of the implant cannot also engage the internal conical connection, sacrificing stability for a better emergence profile. Seating the wide abutment on the shoulder of the implant can present problems if a wide transfer and healing collar was not also selected. A much simpler and less confusing design would have been to make the connection on the 3 widest implants the width of the wide abutment. There is no situation where a wider abutment on wide implants is not more desirable. As you can from the O’Brien video and the Straumann chart below, the current design is confusing.

MISCONCEPTION – Narrower Neck reduces crestal stress:

The thread diameter of the wider implants are greater than the diameter of neck of the implant. That difference increases with the wider implants. Straumann claims the narrow neck reduces stress at the crest. What it does in actuality, is reduce stability because of lack of contact with crestal cortical bone. It also leaves a gap at the crest of the ridge that could encourage soft tissue down growth into the crevice.

MISCONCEPTION – BLX is “Fully Tapered”:

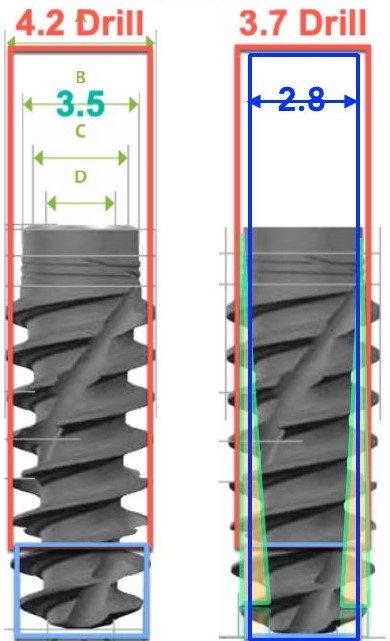

The BLX implants are basically straight with only a slight reduction in diameter to the outside thread diameter below the top 12mm. Forcing a wide apex of an implant into an undersized socket increases the risk of bone fracture and may cause the implant to not fully seat, even when using the widest drills recommended for dense bone. BLX’s final seating in dense bone may require the reverse cutting grooves to enlarge the site by turning more bone into bone chips. This video shows that for a 4.5mmD implant, final sizing with a 4.2mmD drill may not be enough bone reduction to fully seat the implant. The concept of inserting a tapered implant into an undersized socket was first explained in a 1995 patent (Niznick U.S Pat #5,427,527) and documented in a 2000 Niznick Journal Article.

MISCONCEPTION – Deep threads increase initial stability:

Straumann recommends different drill sequences for soft, medium and dense bone. For a 4.5mmD implant in soft bone, a 2.8mmD drill is recommended for final sizing. Forcing an implant into a socket about half its diameter increases the risk of fracturing the bone. Even then, only about half the depth of the apical threads are engaging bone with bone chips filling the void. In medium bone, a 3.7mmD final sizing drill is recommended. This results in only about 1/3 of the depth of the threads engaging bone initially. In dense bone, a 4.2mmD final sizing drill is recommended. This results in only 4.5-4.2/2 = 0.15mm of thread/bone engagement. BLX’s surgical protocol of going back and forth using the bi-diretional cutting grooves to to fully seat the implant will reduce stability.

Comments by dentists on LinkedIn regarding the initial stability of the BLX implant:

Predominant design shortcomings of the BLX implants are:

- One platform for 7 diameters compromises strength of abutments and emergence.

- One platform for 7 diameters creates the need for wider abutments that seat on the shoulder, sacrificing the friction-fit of the 7 degree conical connection and creating confusion as to the right healing collars and transfer components to use.

- The threads and blasted surface run up to the top of the implant, risking.

- The body is straight on 6-12mm implants, and only tapers on the apex of longer.

- The deep threads create space for bone chips rather than compression of soft.

- The bi-directional spiral cutting grooves with “claw-like” cutting edges creates bone chips and sluiceway for ejecting the bone chips out of the socket.

- The BLX implant has a US List Price of $539.

Straumann introduced the BLC and TLC implants in 2024. They have the body shape and threads of the BLT. All diameters have the same internal TorqFit connection and Spiral bi-directional cutting grooves of the BLX and TLX implants. The shorter internal TorqFit connection (3mm BLC vs 4.6mm BLT) allows for fabrication of 6mm bone level implants. The BLC/TLC and the BLX/TLX implants together are marketed as the “iEXCEL™” System, claiming the choice of the four implants offers simplicity and versatility.

Straumann introduced the BLC to compensate for the shortcomings of the BLX. It’s marketing strategy of trying to differentiate indications for the C-Design vs. the X-Design basically advertises that neither are versatile enough to be used for all indications.

Paragon’s TriFit™ Implant offers surgical and prosthetic compatibility with Straumann’s BLT implant – with design improvements for added simplicity and versatility.

Design Advantages of TriFit vs Straumann’s BLT Implants

- TriFit has a 2mm anodized, machined neck with 1mm and 5mm depth gauge lines.

- TriFit has progressively deeper threads for increased stability and surface area.

- TriFit has triple lead threads for 3X faster insertion.

- TriFit’s bi-directional cutting grooves eliminate the need for bone taps, simplifying surgery.

- TriFit’s 8mm implant can be inserted 6mm in bone with its 2mm neck supra-crestal.

Clinical Advantages of TriFit’s single vs Straumann’s iExcel 4 Implants

- TriFit’s 2mm machined neck with depth gauge lines facilitates supra-crestal or bone level.

- TriFit is equally suited for healed sites and immediate insertion into extraction sockets.

- TriFit offers 2 platforms vs iEXCEL’s single platform for a more natural emergence profile.

- TriFit offers “SIMPLICITY YOU’LL LOVE” and “TRUE CLINICAL VERSATILITY”.

- TriFit offers UNPRECEDENTED VALUE at 75% savings based on US list prices.

TriFit match BLT’s Diameters and Lengths for Surgical Compatibility and BLT’s Connections for Prosthetic Compatibility.

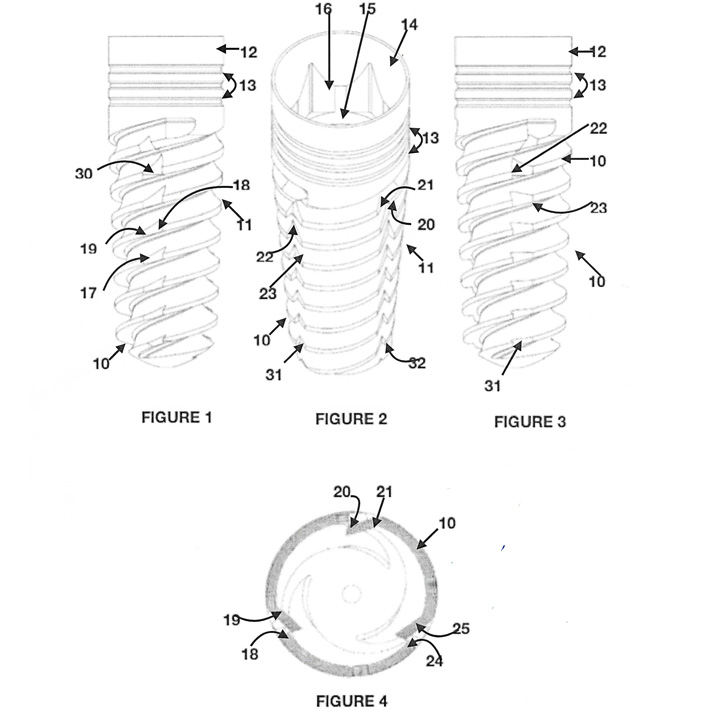

TriFit’s Bi-directional cutting grooves (Pat. Pend.) - 2 for insertion/1 for enlarging socket.

TriFit Implants match BLT's lengths of 8-16mm. TriFit's 2mm machined/anodized neck allows it to be placement Bone Level or Tissue Level. The shortest BLT implant, because of the very deep CrossFit connection, is 8mm. The 8mm TriFit can be placed only 6mm in bone with the machined, anodized neck supra-crestal.