Controversial Issues that Effect the Dental Implant Industry

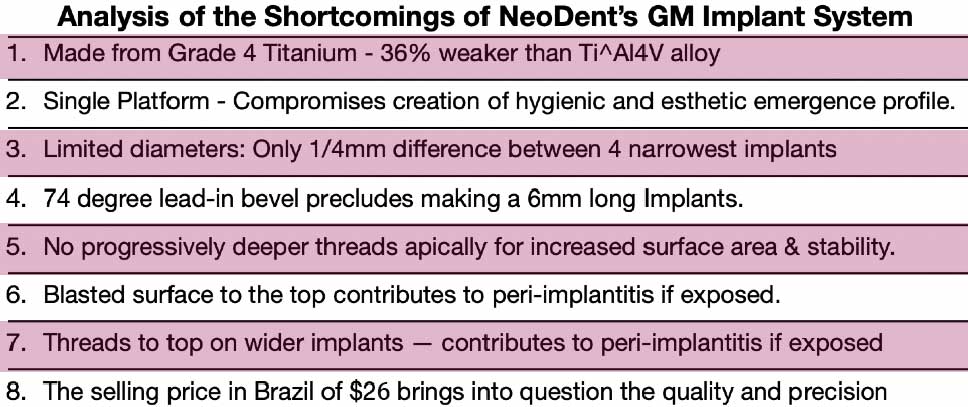

Analysis of the Shortcomings of NeoDent's® GM Implant System

January 12, 2026 | Dr. Gerald Niznick

Share this Post:

Neodent’s GM Implant is basically straight with a Tapered Apical Region.

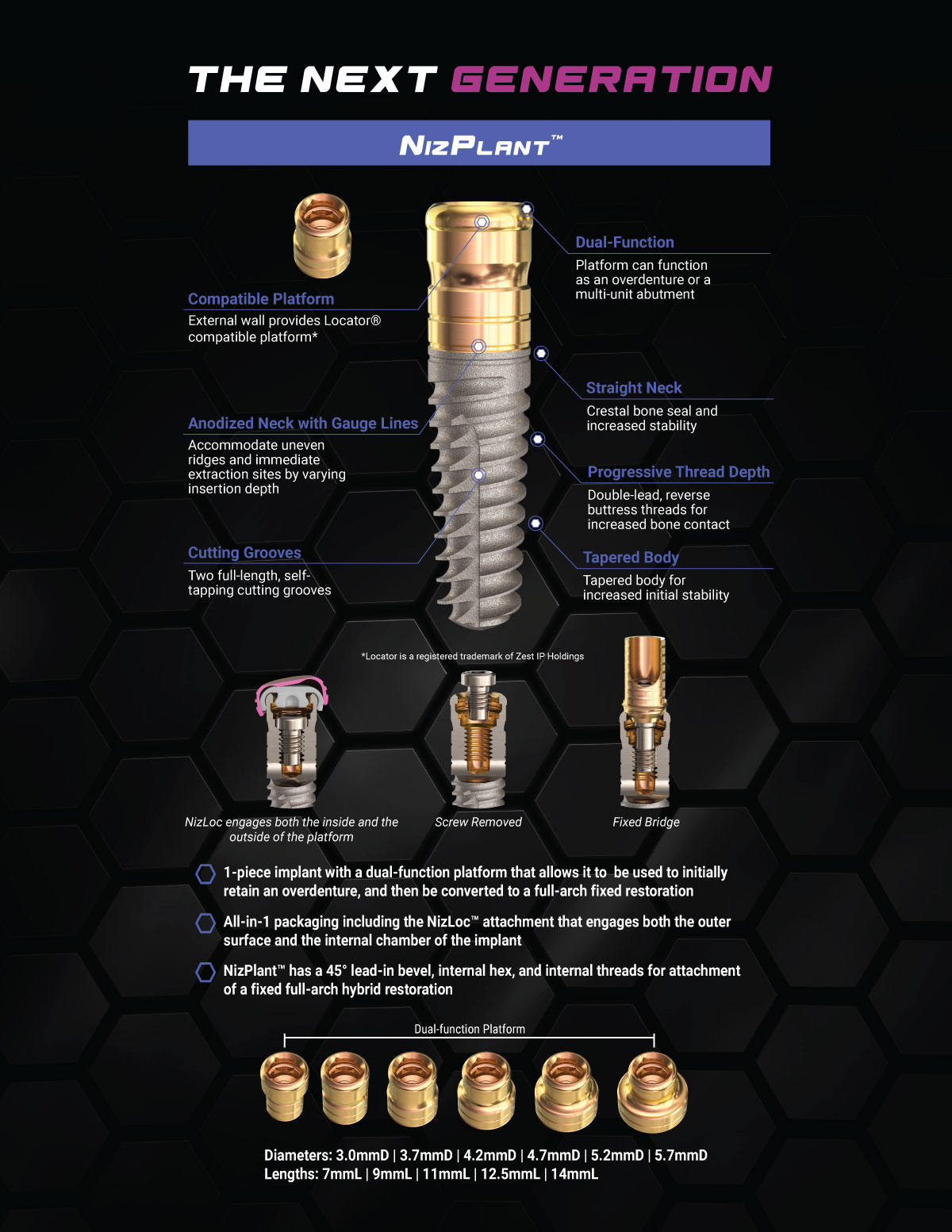

The Neodent GM implant is primarily straight with a tapered apex. A tapered implant inserted into an undersized socket in soft bone will compress the bone and increase initial stability. The Tapered Screw-Vent (1999) introduced a soft-bone surgical protocol, a process documented in a 2000 article by G. Niznick, the developer of the Tapered Screw-Vent (sold to ZimVie’s predecessor in 2001). In 2022, ZimVie documented the 20-year results of the Tapered Screw-Vent, its flagship product, in a video. The exact same tapered concept and surgical protocol with step drills was adopted by Implant Direct for its Legacy implants and is incorporated in the GEN5™ surgical protocol.

Price does not determine quality, but a very low price is only possible if the cost of manufacturing is also minimized. Neodent’s Brazilian shopping cart showed these prices in Brazil. At the January 2026 rate of exchange, the cost in Brazil for a Neodent GM implant with the “Acqua” surface is $26 compared to $289 in US. The shortest implant in this system is 9mm and the diameter options make little sense with only 1/4mm between the 3.5mmD, 3.7mmD, and 4.0mm implants.

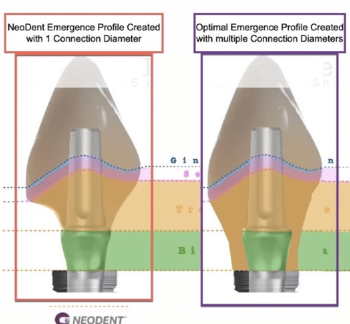

Neodent’s long conical connection and single platform results in a poor emergence profile. The Neodent implant usually requires sub-crestal placement of the implant-abutment junction in order to provide enough “running room” to flare from the top of the implant to the restoration. Studies have shown that sub-crestal placement of the implant-abutment junction compared to supra-crestal placement, contributes to bone loss and subsequent peri-implantitis.

The lead-in bevel on the Neodent “Grand Morse” implant is 16 degrees off the vertical center line (74 degrees off the horizontal). A Morse Taper is an engineering term describing mating surfaces each with about 1.5 degree taper, creating a friction fit. For a conical connection to be effective at sealing the internal shaft against the ingress of bacterial, the bevel of the abutment needs to be 0.5 degree flatter than the bevel of the implant. As shown in this cross section of a Neodent implant and abutment from Neodent’s own marketing material, it is evident that the first contact between the taper on the abutment and the taper on the implant is occurring below the top, indicating either poor design or poor precision. Increasing the angle of the bevel increases the depth of the hex, thinning the walls of the implant and precluding making short implants.

The lead-in bevel on the Neodent “Grand Morse” implant is 16 degrees off the vertical center line (74 degrees off the horizontal). A Morse Taper is an engineering term describing mating surfaces each with about 1.5 degree taper, creating a friction fit. For a conical connection to be effective at sealing the internal shaft against the ingress of bacterial, the bevel of the abutment needs to be 0.5 degree flatter than the bevel of the implant. As shown in this cross section of a Neodent implant and abutment from Neodent’s own marketing material, it is evident that the first contact between the taper on the abutment and the taper on the implant is occurring below the top, indicating either poor design or poor precision. Increasing the angle of the bevel increases the depth of the hex, thinning the walls of the implant and precluding making short implants.

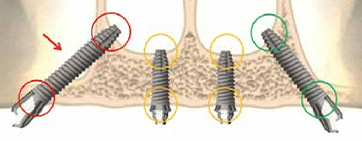

Full Arch Masters posted this image claiming: “anchoring implants into the deep cortical plates of the maxilla… aids in primary stability in soft bone [and] also improves long term stability as the bone rarely remodels over time.” They acknowledged the potential negative effects of perforating the floor of the nose but state: “However, placement of these implants often results in invasion into the nasal cavity, which is not without risk. We assume this risk because of the benefits.”

A more conservative treatment plan is to place six implants between the maxillary sinuses and not engage or perforate the floor of the nasal cavity. Stability is achieved by inserting a tapered implant with progressively deeper threads, self-tapping into an undersized socket to compress the bone between the threads. Stability of 30+ Ncm can be achieved regardless of length. Six implants placed in the anterior provide redundancy should one or even two of the implants fail.

Fig. 1a shows distal Neodent 18mm long implants placed at about 45 deg. The dentist said that 16mm long implants were not stable so he went back with longer implants to engage the cortical bone under the nose. Note that the majority of the length of the Neodent implants is straight with just the apical portion tapered. A tapered implant will achieves good initial stability in soft bone.

Fig. 1b Based on this panoramic x-ray, six GEN5+™ implants of varying lengths could be placed – Note the improved emergence profile.

Fig. 2a shows six Neodent implants all placed below the yellow line which represents the 2D image of the highest level of the ridge, probably on the lingual. Three of the implants have angled abutments.

Fig. 2b Six GEN5+™ implants placed over the Neodent implant images with the implant-abutment junction level with the bone image. If the ridge slopes down to the labial, GEN5’s™ 2mm machined surface assures that its blasted surface will not be exposed to the soft tissue. Paragon’s™ ASC copings will correct the angle.

Paragon’s GEN5™ emergence profile with machined neck more conducive to good oral hygiene. Neodent’s GM implants, with threads & blasting to top, are more conducive to peri-implantitis.

These side-by-side images demonstrate the advantages of GEN5™ vs Neodent implants.

- The GEN5+™ with its friction-fit 2mm extender provided with each implant, creates a more ideal emergence profile.

- The top 2mm of the GEN5™ and GEN5+™ is an anodized, machined surface. Smoother surfaces on the neck of the implant reduce peri-implantitis.

- The GEN5™ and GEN5+™ implants is evenly tapered in contrast to Neodent with is primarily straight with a tapered apex. The even taper is conducive for initial stability.

- The GEN5™ and GEN5+™ have progressively deeper, reverse buttress threads with the flat facing apically in contrast to the Neodent buttress threads, the flat facing upwards.

- The GEN5™ and GEN5+™ are made from Titanium Alloy which is 36% stronger than Grade 4 Titanium used with the Neodent implants.